Hydrogen Meter is a specialized testing device independently designed and manufactur

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

The Hydrogen Meter is a specialized testing device independently designed and manufactured by our company for qualitative detection of hydrogen content in molten casting aluminum. Despite being an economical model, its simple operation and rapid testing capabilities make it the preferred choice for many experienced manufacturers.

Prinsip kerja

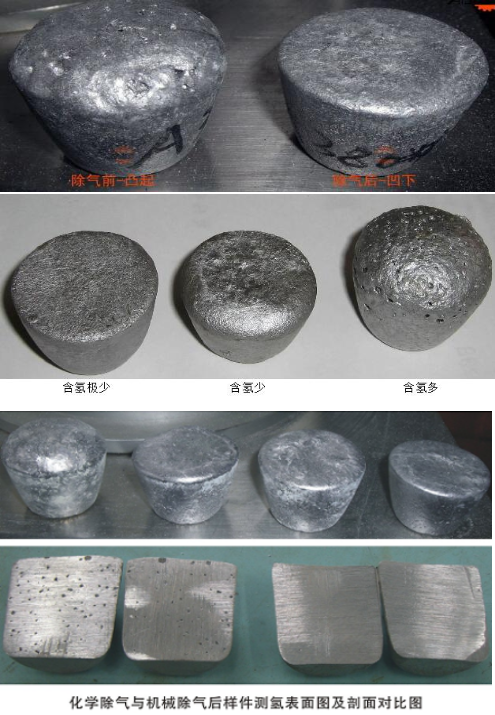

Based on the reduced pressure solidification method, the test sample solidifies under vacuum conditions. During this process, hydrogen dissolved in the molten aluminum gradually precipitates, forming bubbles inside or on the surface of the sample. The hydrogen content is evaluated by:

Key Features:

Sample Evaluation Methods

A. Surface Observation Method

B. Cross-Sectional Porosity Analysis

C. Aluminum Density Measurement

Technical Parameter

| Parameter | Specification |

|---|---|

| Dimensions (L×W×H) mm | 600×500×1400 |

| Weight kg | 120 |

| Sample Weight g | 100 |

| Pumping Speed L/s | 2 |

| Vacuum Range (Adjustable) kPa | -100 to -1.3 |

| Ultimate Vacuum Time min | <4 seconds |

| Vacuum Pump Motor Power kW | 0.37 |

| Pinhole Grade | Number of Pinholes (per cm) | Pinhole Diameter (mm) | Percentage Distribution (%) |

|---|---|---|---|

| 1 | <5 | <0.1 | 90 |

| 1 | <5 | 0.1-0.2 | 10 |

| 2 | <10 | <0.1 | 80 |

| 2 | <10 | 0.1-0.2 | 20 |

| 3 | <15 | <0.3 | 80 |

| 3 | <15 | 0.3-0.5 | 20 |

| 4 | <20 | <0.5 | 70 |

| 4 | <20 | 0.5-1.0 | 30 |

| 5 | <25 | <0.5 | 60 |

| 5 | <25 | 0.5-1.0 | 30 |

| 5 | <25 | >1.0 | 10 |

Penafian: Konten di atas hanya untuk referensi dan komunikasi antara orang dalam industri, dan tidak menjamin akurasi atau kelengkapannya. Menurut hukum dan peraturan yang relevan dan peraturan situs web ini, unit atau individu yang membeli barang terkait harus memperoleh kualifikasi dan kondisi kualifikasi yang valid.

Telepon Perusahaan

+86-21-6420 0566

Jam kerja

Senin sampai Jumat

Telepon seluler:

13816217984

Email:

info@qinsun-lab.com