Waktu: Popularitas0waktu

Textile testing instruments play a critical role in evaluating material performance across diverse industrial applications. This overview categorizes key instruments by function and application:

1. Dyeing and Printing Color Fastness Testers

Designed to assess color resistance to dry/wet rubbing and abrasion during laundering. Features include:

2. General-Purpose Textile Testing Instruments

Used for fundamental material analysis including:

3. Environmental Simulation Chambers

Subject materials to controlled cycles of light, humidity, and elevated temperatures to simulate:

4. Testing Consumables

Essential supplies for standardized evaluations:

5. Flame Retardancy & Protective Performance Testers

Evaluate fabric protection characteristics including:

6. Functional Performance Instruments

Assess textile functionality related to:

7. Physical Property Testers

Measure mechanical attributes without chemical intervention:

8. Chemical Resistance Analyzers

Evaluate material behavior in chemical environments:

9. Curtain/Drapery Flammability Testers

Specialized equipment for vertical flame spread evaluation:

Technical Advancements:

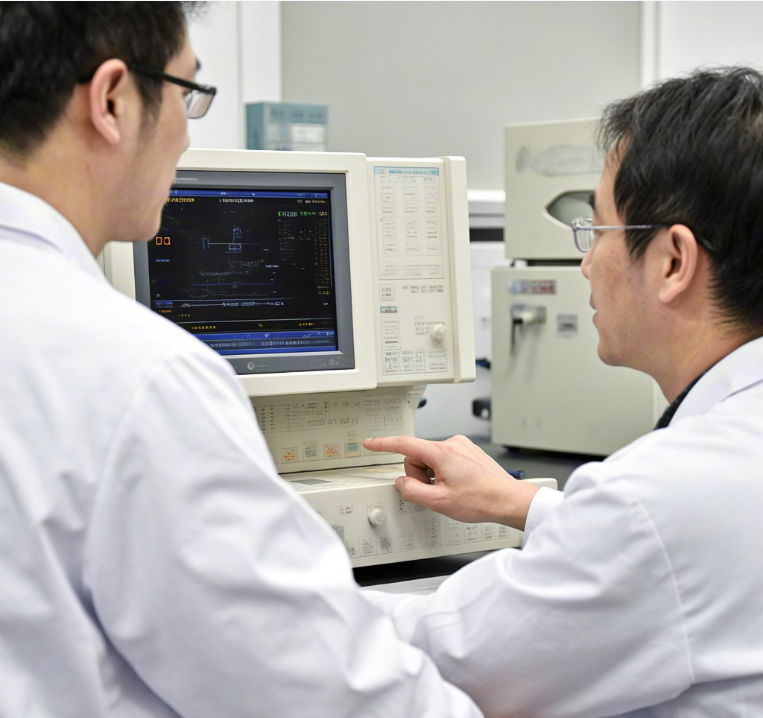

Modern instruments integrate precision mechanics with digital control systems, enabling:

Applications:

These instruments support quality control in:

Conclusion:

Specialized textile testing equipment ensures material performance meets rigorous safety, durability, and functionality requirements across industrial sectors. Regular calibration and adherence to testing protocols are essential for reliable results.

Telepon Perusahaan

+86-21-6420 0566

Jam kerja

Senin sampai Jumat

Telepon seluler:

13816217984

Email:

info@qinsun-lab.com