I. Product OverviewThe Textile Flatness Tester is a precision instrument designed to evaluate fabric

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

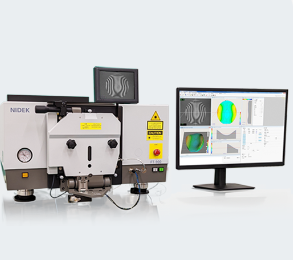

The Textile Flatness Tester is a precision instrument designed to evaluate fabric surface evenness by quantifying thickness variation, weave irregularities, and fiber distribution. It ensures compliance with quality standards for garment manufacturing, upholstery, and industrial textiles.

| Parameter | Specifications |

|---|---|

| Scanning Resolution | 0.1mm x 0.1mm grid mapping |

| Thickness Measurement Range | 0.05-10mm (±0.5% accuracy) |

| Surface Roughness Detection | 0.1-100μm Ra (ISO 4287 standard) |

| Sumber Cahaya | 400-700nm RGB LED array |

| Data Output | 3D topography map + statistical CSV |

| Dimensi | 1500×800×1200mm (L×W×H) |

Penafian: Konten di atas hanya untuk referensi dan komunikasi antara orang dalam industri, dan tidak menjamin akurasi atau kelengkapannya. Menurut hukum dan peraturan yang relevan dan peraturan situs web ini, unit atau individu yang membeli barang terkait harus memperoleh kualifikasi dan kondisi kualifikasi yang valid.

Telepon Perusahaan

+86-21-6420 0566

Jam kerja

Senin sampai Jumat

Telepon seluler:

13816217984

Email:

info@qinsun-lab.com